In a groundbreaking fusion of biology and engineering, researchers have developed 3D-printed fracture repair armor inspired by the remarkable structure of nacre, or mother-of-pearl. This innovative approach promises to revolutionize orthopedic medicine by offering stronger, more flexible, and biocompatible solutions for bone fractures. The natural world has once again provided a blueprint for human innovation, with the layered, brick-and-mortar architecture of seashells guiding the design of next-generation medical implants.

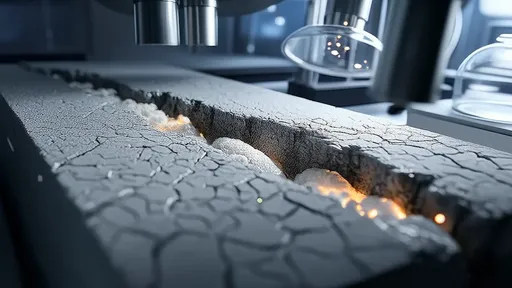

The journey began when materials scientists observed how nacre withstands tremendous pressure while remaining lightweight. Its intricate microstructure – alternating layers of rigid calcium carbonate and elastic biopolymers – creates a material that’s both strong and tough. This natural composite exhibits a unique combination of properties that man-made materials struggle to replicate: high fracture resistance, exceptional durability, and the ability to deflect cracks through intricate architectural pathways.

Traditional fracture repair methods often rely on metal plates and screws, which present several limitations. These rigid implants can cause stress shielding, where the metal assumes too much load, leading to bone weakening over time. Additionally, their non-biodegradable nature frequently necessitates secondary surgeries for removal. The nacre-inspired armor addresses these issues through a fundamentally different design philosophy that mimics biological systems rather than opposing them.

Using advanced 3D printing techniques, researchers can now recreate nacre’s complex microstructure with unprecedented precision. The process involves depositing alternating layers of ceramic nanoparticles and polymer binders, building up the material micron by micron. What emerges is a synthetic material that rivals nature’s ingenuity – stiff enough to support healing bones yet flexible enough to move with them, reducing the risk of implant failure.

The manufacturing breakthrough lies in multi-material additive manufacturing systems capable of precisely controlling composition and structure at microscopic scales. These printers can vary material properties within a single implant, creating gradient transitions that mirror natural tissue interfaces. Such capabilities allow for customized solutions tailored to individual patients’ anatomy and specific fracture patterns, a significant advancement over one-size-fits-all metal plates.

Early clinical trials have shown remarkable promise. The bioinspired armor not only provides mechanical support but also encourages bone regeneration. Its porous architecture allows for vascular ingrowth and nutrient transport, while the ceramic components slowly dissolve, releasing calcium ions that stimulate new bone formation. This dual functionality represents a paradigm shift from passive support to active participation in the healing process.

Beyond fracture repair, this technology opens doors to numerous medical applications. Researchers envision versions that deliver drugs or growth factors, smart implants that monitor healing progress, and even biodegradable variants that completely dissolve as bone regenerates. The principles learned from nacre could also inform the development of other biomedical devices, from dental implants to spinal fusion cages.

As with any medical innovation, challenges remain before widespread clinical adoption. Long-term studies must confirm the material’s durability and biological compatibility. Regulatory approvals will require extensive testing, and manufacturing processes need scaling for cost-effective production. However, the potential to transform fracture treatment makes this a compelling area of research that bridges materials science, biology, and clinical medicine.

The success of nacre-inspired implants highlights the growing field of biomimetic medicine, where evolutionary solutions inform human technology. From gecko-inspired adhesives to shark skin-derived antibacterial surfaces, nature continues to provide elegant solutions to complex engineering problems. In the case of fracture repair, the humble mollusk may hold the key to healing bones more effectively than ever before.

Looking ahead, researchers aim to enhance the material’s properties further by incorporating living cells during the printing process. This approach could yield truly biological implants that seamlessly integrate with host tissue. Other teams are exploring stimuli-responsive versions that adapt their stiffness in response to mechanical loading, mirroring how natural bone remodels under stress.

The convergence of 3D printing and biomimicry represents a new frontier in personalized medicine. As these technologies mature, patients may soon benefit from implants that don’t just repair damage but actively participate in regeneration. The lessons from nacre demonstrate that sometimes, the most advanced solutions come not from rejecting nature, but from understanding and emulating its billion-year-old designs.

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025