In a groundbreaking leap for robotics, researchers have unveiled a new class of actuators powered by liquid metal alloys—materials that blur the line between solid and fluid. These reconfigurable soft actuators promise to revolutionize everything from medical devices to search-and-rescue robots, offering unprecedented flexibility and adaptability. Unlike traditional rigid components, these systems can morph their shape dynamically, enabling movements that were once the exclusive domain of science fiction.

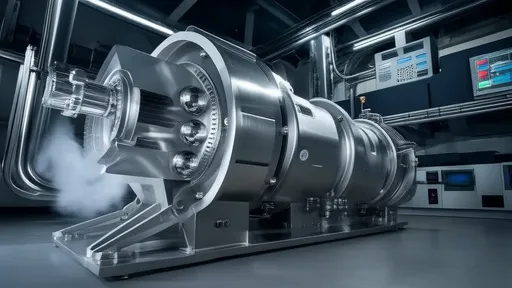

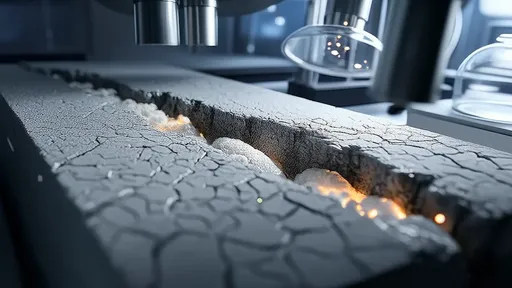

The core innovation lies in the use of gallium-based alloys, which remain liquid at room temperature while exhibiting metallic conductivity. When subjected to electrical or magnetic fields, the liquid metal redistributes itself, creating localized changes in stiffness and geometry. This property allows a single actuator to perform multiple functions—stretching, twisting, or stiffening on demand—without requiring complex mechanical assemblies. Early prototypes have demonstrated the ability to navigate tight spaces, self-heal after damage, and even split into smaller units before recombining.

What sets this technology apart is its biomimetic potential. The actuators mimic the behavior of organic muscles and tendons more closely than any previous artificial system. During tests, researchers observed liquid metal appendages executing delicate tasks like picking up a raw egg or threading a needle—feats impossible for conventional robotic arms. This opens doors for surgical robots capable of navigating fragile human tissues with minimal risk of trauma.

Challenges remain in scaling up the technology for industrial applications. Controlling the liquid metal's flow with precision requires sophisticated algorithms that account for fluid dynamics, surface tension, and electromagnetic interference. Researchers are developing hybrid systems where traditional sensors are embedded within the liquid matrix, creating a feedback loop that adjusts the actuator's behavior in real time. Recent breakthroughs include the integration of machine vision systems that allow the actuators to "see" and adapt to their environment autonomously.

The military and aerospace sectors have taken particular interest in these developments. DARPA has funded several projects exploring liquid metal actuators for morphing aircraft wings and self-assembling reconnaissance drones. Unlike conventional folding mechanisms, liquid-based systems require no hinges or joints—the entire structure can flow into a new configuration, reducing mechanical failure points. Similarly, NASA is investigating the technology for space applications where extreme temperature fluctuations would render ordinary materials useless.

Environmental considerations are shaping the research trajectory. While gallium alloys are non-toxic, their large-scale deployment raises questions about resource availability and recycling. Scientists are experimenting with alternative mixtures incorporating indium and tin to optimize performance while reducing reliance on rare elements. Another promising avenue involves creating liquid metal composites by suspending nanoparticles in the alloy, which could enhance strength without sacrificing fluidity.

Commercialization efforts are already underway, with startups racing to patent liquid metal actuation methods. One company has demonstrated a prototype robotic gripper that can adjust its hardness to handle objects ranging from a wine glass to a wrench. Another venture is developing wearable exoskeletons where liquid metal actuators provide seamless assistance without bulky hydraulic systems. Industry analysts predict the first medical applications could reach clinical trials within five years.

Perhaps the most profound implication lies in the philosophical shift this technology represents. For decades, robotics followed a paradigm of rigid precision. Liquid metal actuators suggest an alternative future where machines embrace fluidity and impermanence—qualities inherent to biological life. As research progresses, we may witness the emergence of robots that can literally pour themselves into new forms, challenging our fundamental notions of what machines can be.

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 9, 2025